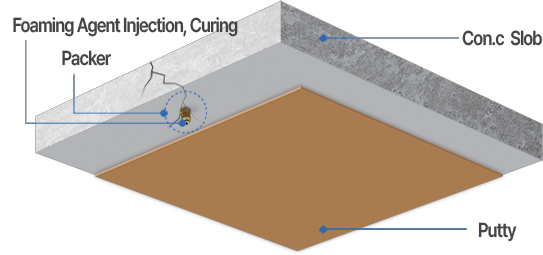

Ceiling waterproofing using injection method

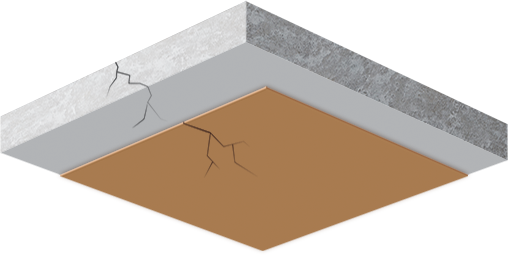

Leakage reoccurs over time

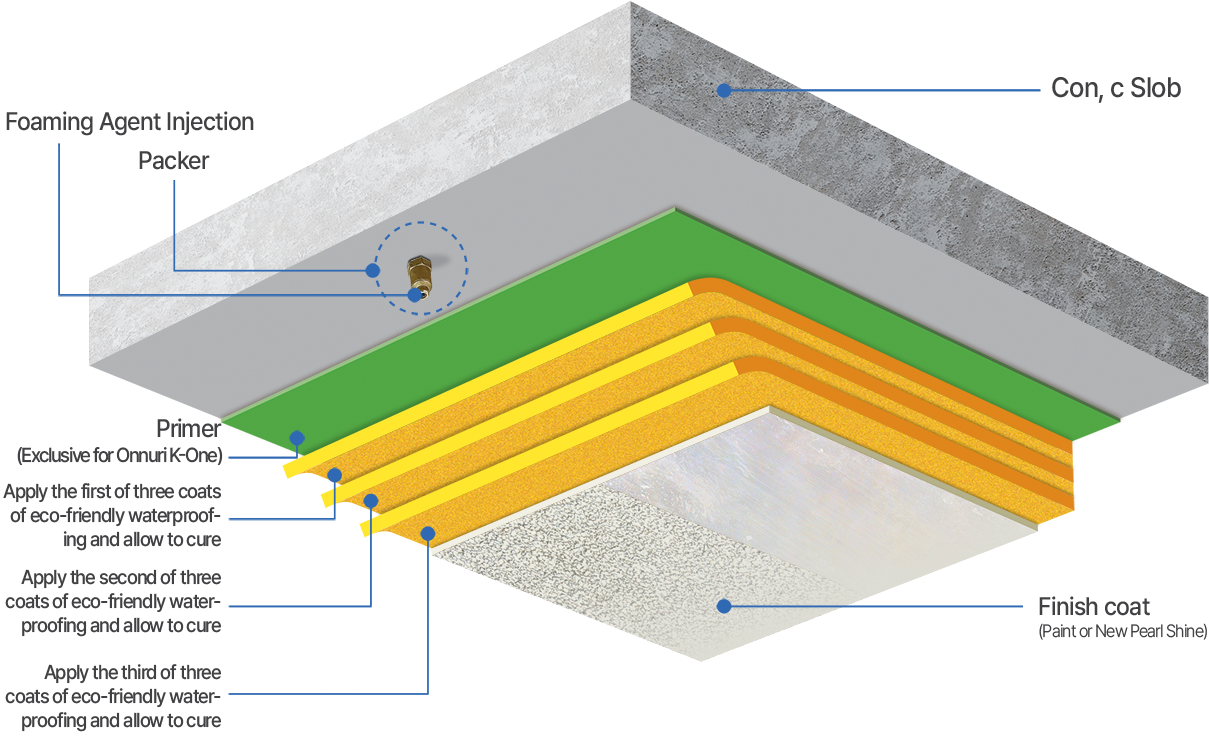

Construction Method Procedure

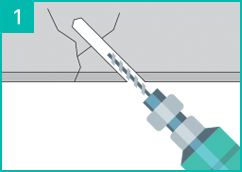

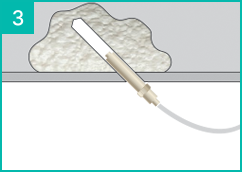

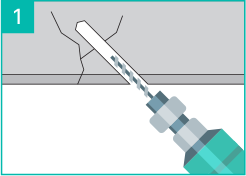

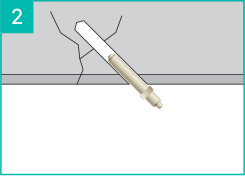

Drill into cracked, leaking parts of ceiling

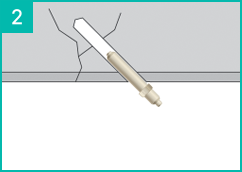

Insert packer

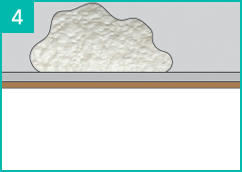

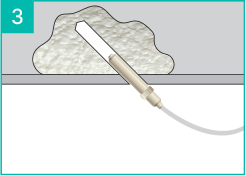

Inject foamed urethane

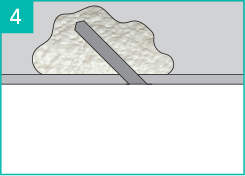

Apply putty

Due to earthquakes and vibrations

Due to structural movement

Due to vehicle traffic

The eco-friendly inorganic-based high-elasticity waterproofing does not crack or fail.

When leakage occurs in a Con.c Slab ceiling, a foaming agent is injected into the crack through a packer. It reacts with water, expanding like a sponge to temporarily block the flow of water but this is not a waterproofing material.

NOOSTOP’s New Concept and Method for Ceiling Waterproofing

Patented Eco-Friendly Waterproofing Product / Patented Construction Method

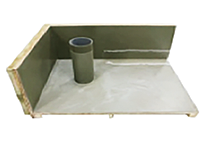

Con.c Slab – Ceiling leakage in underground parking lots

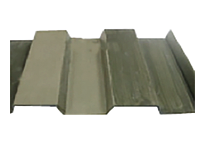

Deck plates and metal joints – Joint leakage

Classrooms, offices, and underground electrical rooms – Ceiling leakage

Subway and tunnel ceilings Ceiling leakage

Apartment units on each floor, ceiling verandas Ceiling leakage

Ceiling waterproofing 100% perfect application

(Warranty Insurance Certificate Issued)

Drill into cracked, leaking areas on the ceiling

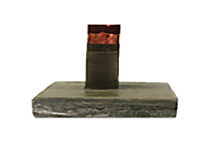

Insert packer and inject foaming agent (allow to cure)

Inject foamed urethane

Apply K303 Concrete Putty for surface restoration

Apply primer and allow to cure

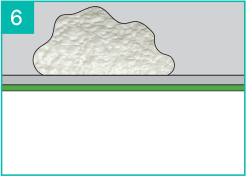

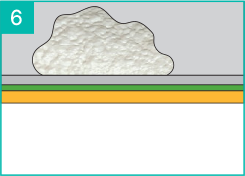

Apply the first of three coats of eco-friendly waterproofing and allow to cure

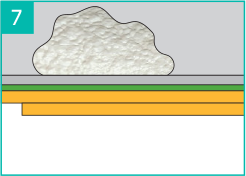

Apply the second of three coats of eco-friendly waterproofing and allow to cure

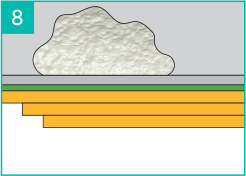

Apply the third of three coats of eco-friendly waterproofing and allow to cure

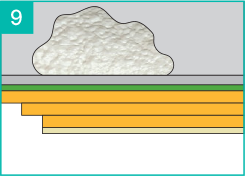

Reapply finish coat (Paint or New Pearl Shine)

The eco-friendly inorganic-based high-elasticity waterproofing does not crack or fail.

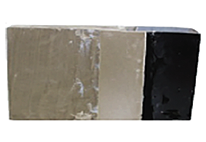

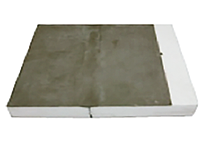

Application of eco-friendly inorganic-based ECO-K high-elastic waterproofing material

Backside of paving block damaged

Waterproofing layer remained undamaged

Waterproofing layer remained undamaged

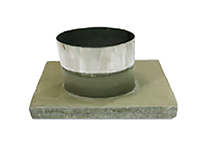

PVC/Steel pipe

Stainless steel pipe

PE pipe

Copper pipe

Sloped rock surface

Steel plate, rebar, H-beam

L-angle

Deck plate joint

Aluminum sash

High sash

Plywood

Styrofoam joint